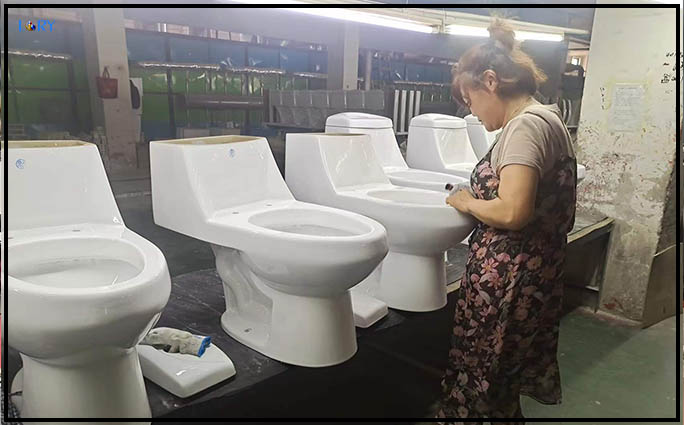

When ceramic manufacturing enterprises process and sell products, they usually need to inspect the appearance defects and functions of product quality. As a factory specializing in the production and manufacture of ceramic sanitary ware, we are very familiar with the appearance defects and functional testing items of ceramic products. Today, we will popularize this knowledge for wholesaler customers who want to import ceramic sanitary ware, so as to develop wholesale business in the future lay the foundation.

1. Common appearance defects of ceramic products

Crack: A crack that runs through the embryo body and glaze.

Embryo fissure: A crack in the embryo body.

Glaze Cracks: Cracks in the glaze.

Big bag: the raised part of the surface whose maximum size exceeds 3MM.

Small package: the raised part of the surface with a maximum size of 1-3MM.

Glaze blister: The raised part of the surface whose maximum dimension does not exceed MM.

Brown eye: A small hole with a maximum size of no more than 2MM on the glaze.

Cave: A small hole with a maximum size greater than 2MM on the glaze.

Spots: Heterochromatic spots not exceeding MM in maximum dimension.

Large piebald spots: heterochromatic spots with a maximum size of 3-6MM.

Small piebald spots: heterochromatic spots with a maximum size of 1-3MM.

Spots: heterochromatic areas with the largest dimension exceeding 6MM or heterochromatic areas formed by dense spots

Ripple: A defect in which the glaze presents a wavy pattern.

Glaze shrinkage: The glaze surface gathers and shrinks so that the embryo body is partially unglazed.

Lack of glaze: There is no glaze on the surface of glazed products.

Glaze wisps: streaks or drops of glaze with protrusions on the glaze surface

Orange glaze: The glaze surface is like orange peel, with poor luster.

Germ powder: Defects caused by unremoved sludge or glaze slag under the glaze.

Peeling: The strip-like peeling off of the edge of the glaze layer.

Pockmarked surface: The sunken pit that appears on the front of the product.

2. Toilet function detection:

A: Test according to the method specified in the standard, the average water consumption is not more than 6.0L:

B: Water seal ≥ 50mm, water seal recovery ≥ 50mm:

C: The test method uses 100 polypropylene balls to be washed three times in a row, and the average number is not less than 85.

D: Ink line test: the total length of the cumulative residual ink line after each flushing is not greater than 50mm, and the length of each residual ink line is not greater than 13mm;

E: Half-row paper towel test: Half-row flushes 6 toilet papers, 5 passes at least 4 times:

F: Full row paper towel test: flush 12 toilet paper in full row, pass at least 4 times in 5 times

3. Toilet installation size and identification:

A: There are two screw mounting holes with a diameter of 12mm on the back of all water tanks, and one water inlet hole. There is a 6L☑ water level line inside the water tank. The actual water level is no more than 10m higher than the 6L water level line; cover the upper part of the water level line with “6L” seal. All water fittings should be installed tightly and adjusted properly, and installed in the state of use.

B: All toilets must have two anchor screw holes.

C: The diameter of the sewage outlet of all toilets should be 100mm; the length should be at least 50mm, and at least it should be guaranteed that it will not leak after being installed with the sewage pipe

D: The distance from the center of the sewage outlet to the ground is 180+5mm/180-10MM.

E: The size of the opening holes for all water tank installations must be consistent with the size of the toilet installation holes, and must be completely consistent with the installation of the toilet.

F: The ceramic horizontal sewage pipe is cylindrical, not conical, and the slope should not be too large. After being installed with the plastic sleeve, it needs to be kept perpendicular to the ground.

G: All toilets must have two cover mounting holes, the size of which must be consistent with the cover.

H: All air holes shall be kept as they are, and repairs are not allowed. All splits and basins must be tested for static leakage. If water leakage is found in the air holes, they must be resolutely scrapped.

4. Column and washbasin

A: Basin single-hole faucets are installed with a diameter of 35mm.

B: There must be four installation holes on the back of all pots, two large oval installation holes with a diameter of 20mmx30mm and two small installation holes with a diameter of 12mm

C: The diameter of the sub-hole of the double-hole faucet for the basin is 28mm-30mm, the center distance is 204mm., and the diameter of the chain hole is 7.5mm (only the product with double holes has the chain f hole).

D: The ventilation hole of the basin and the chain subhole of the twin hole basin must be higher than the center line of the overflow hole to prevent the product from leaking.

E: The height of the column basin should be 800mm-850mm after installation.

F: The diameter of the water outlet of the basin is 45mm. Depth 51+6/51-6MM

G: All the uprights of the pedestal basin must be fully open and have two installation holes for anchor screws.

H: Pots must have a round overflow hole and must be fitted with an overflow buckle.

The above are the quality inspection items to be carried out before the ceramic products leave the factory. The stricter the quality control of ceramic sanitary ware manufacturers, the more perfect the products delivered to customers. Our LORY ceramic sanitary ware factory has been believing in three principles for many years, that is , do not accept substandard products, do not manufacture substandard products, and do not deliver substandard products. It is the belief in and adherence to these principles that has won the trust of our wholesaler customers time and time again. If you also want to start ceramic sanitary ware wholesale business, please contact us without hesitation.