When purchasing a toilet, most people will focus on the appearance, functionality and flushing method, but often ignore the most important material – ceramic body.

At first glance, there is no obvious difference between the porcelain body.

However, whether the toilet is easy to clean and whether it is easy to stain, yellow and other problems is directly related to the porcelain body.

The porcelain body of the toilet mainly consists of two parts:

the embryonic body and the glaze, which is similar to the relationship between a tree trunk and bark.

1. Porcelain body raw materials

a. Place of origin

The origin of ceramics will affect the quality of raw materials.

China has eight major ceramic production areas: Foshan in Guangdong, Tangshan in Hebei, Chaozhou in Guangdong, Jingdezhen in Jiangxi, Dehua in Fujian, Zibo in Shandong, Liling in Hunan, and Yixing in Jiangsu.

Among them, Foshan in Guangdong and Tangshan in Hebei are particularly famous and are known as the pottery capital of the South and the porcelain capital of the North.

Well-known toilet brands and manufacturers are also mainly concentrated in the above areas.

b.Raw materials

The raw materials for making ceramics include clay, feldspar and quartz.

Among them, clay is the main binder, combining feldspar and quartz and other materials; feldspar is the main flux, which can reduce the sintering temperature of silica (quartz) in ceramics;

quartz has a high melting point and plays a role in the sintering process.

The function of the skeleton is to generate expansion during the sintering process to reduce drying and sintering shrinkage,

which can increase the wear resistance, strength and chemical stability of the green body and glaze.

2. Calcination

After the embryo is formed, it is fired in a kiln.

According to the temperature, it can be divided into low temperature kiln, medium temperature kiln and high temperature kiln.

a. Firing temperature

The low-temperature kiln firing temperature is about 700-900 degrees, and the firing time is about 8 hours;

the medium-temperature kiln firing temperature is 1000-1150 degrees;

the high-temperature kiln firing temperature is above 1200°C.

The higher the temperature, the higher the requirements on the kiln and the longer the firing time.

Good toilet porcelain bodies are calcined in high-temperature kiln production lines, with a firing temperature of 1280°C and a firing time of more than 20 hours.

b. Ceramicization

The high-temperature kiln can burn the entire embryo body through, showing a transparent porcelain state.

Because the temperature is high, the crystal density of the glaze is high, which can remove more impurities.

The porcelain is whiter and purer, has low water absorption, is easy to clean and does not absorb odors.

In medium and low temperature kilns, because the porcelain body is fired at a low temperature and the firing time is short,

the interior of the body has not been fully calcined and cannot complete the “crystallization transformation”.

Therefore, the material has high voids, high water absorption, and is prone to yellowing. , not easy to clean.

The cost of fuel and supporting raw materials for high-temperature kilns is much higher than that of medium- and low-temperature kilns.

Some small workshops use medium- and low-temperature kilns to bake toilets in order to save production costs.

3. Glazed surface

After the embryo body is calcined and dried, a layer of glaze is applied to its surface,

and then sintered at high temperature to form a glass phase substance on the surface of the porcelain body, which is the glaze.

The problem of toilet stains and yellowing is directly related to the quality of the glaze.

A good glaze is hard and dense, not prone to scratches, dirt, and yellowing after long-term use.So, how to tell whether the glaze is good or bad?

a. Look at the glaze style

Glaze type, that is, the mixing ratio of glaze.

The glaze formula of each manufacturer is not exactly the same, and the raw material boric acid has very high purity requirements.

Generally, well-known sanitary ware manufacturers will use imported boric acid. Under the same manufacturing conditions and process level, the glaze using imported boric acid will have better gloss, fewer pores, and is less likely to stain.

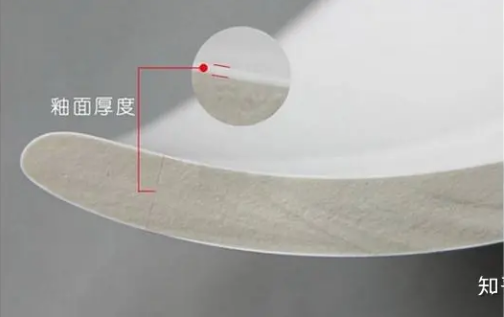

b. Look at the thickness of the glaze layer

The thickness of a good glaze layer is generally more than 0.8mm.

The high-quality glaze adopts the glaze pouring process and adds titanium oxide and phosphide (i.e. bone powder) to the glaze to increase the concentration and whiteness of the glaze,

thereby improving the refractive index of the glaze.

When purchasing a toilet, you should observe the porcelain body to see if its surface is smooth;

at the same time, touch it with your hands.

The smoother and more delicate the touch, the better the texture of the glaze.

4. Anti-fouling test

The basic function of a toilet lies in its ability to discharge and resist pollution.

How to judge whether a toilet’s sewage discharge and anti-sewage capabilities meet the standards?

a. Small ball test

Put 100 polypropylene balls with a diameter of 19±0.4mm and a weight of 3.05±0.15g into the toilet,

start the flushing device, check and record the number of balls flushed out of the toilet drain outlet.

It is carried out three times in a row, and the average number of the three punches is not less than 85 to be qualified, otherwise it is deemed to be unqualified.

b. Ink line test

Use a soft pen to draw a circle of ink lines around the inner wall of the toilet at a depth of 25 mm,Flush immediately.

If no ink marks are left or the total length of the ink lines is no more than 50 mm, and the length of the remaining ink lines in each section is no more than 13 mm, the toilet is qualified.

Otherwise, it is unqualified.